Table of content

- Introduction

- Energy Requirement in Cement Industry

- How Cement Industry Will Benefit From the Solar Transition?

- Government Regulations and Policies

- Sunsure's Role in Decarbonization of Cement Industry

- Conclusion

The cement industry in India has long been a key player in the country’s infrastructure development. However, with increasing environmental concerns and a growing global emphasis on sustainability, the Indian cement sector is undergoing a transformation. Companies are now actively pursuing sustainable practices to align with environmental goals and societal expectations. The integration of solar energy into cement manufacturing heralds a new era of environmental stewardship and economic efficiency. This article explores the journey of the cement sector towards a sustainable future powered by solar energy.

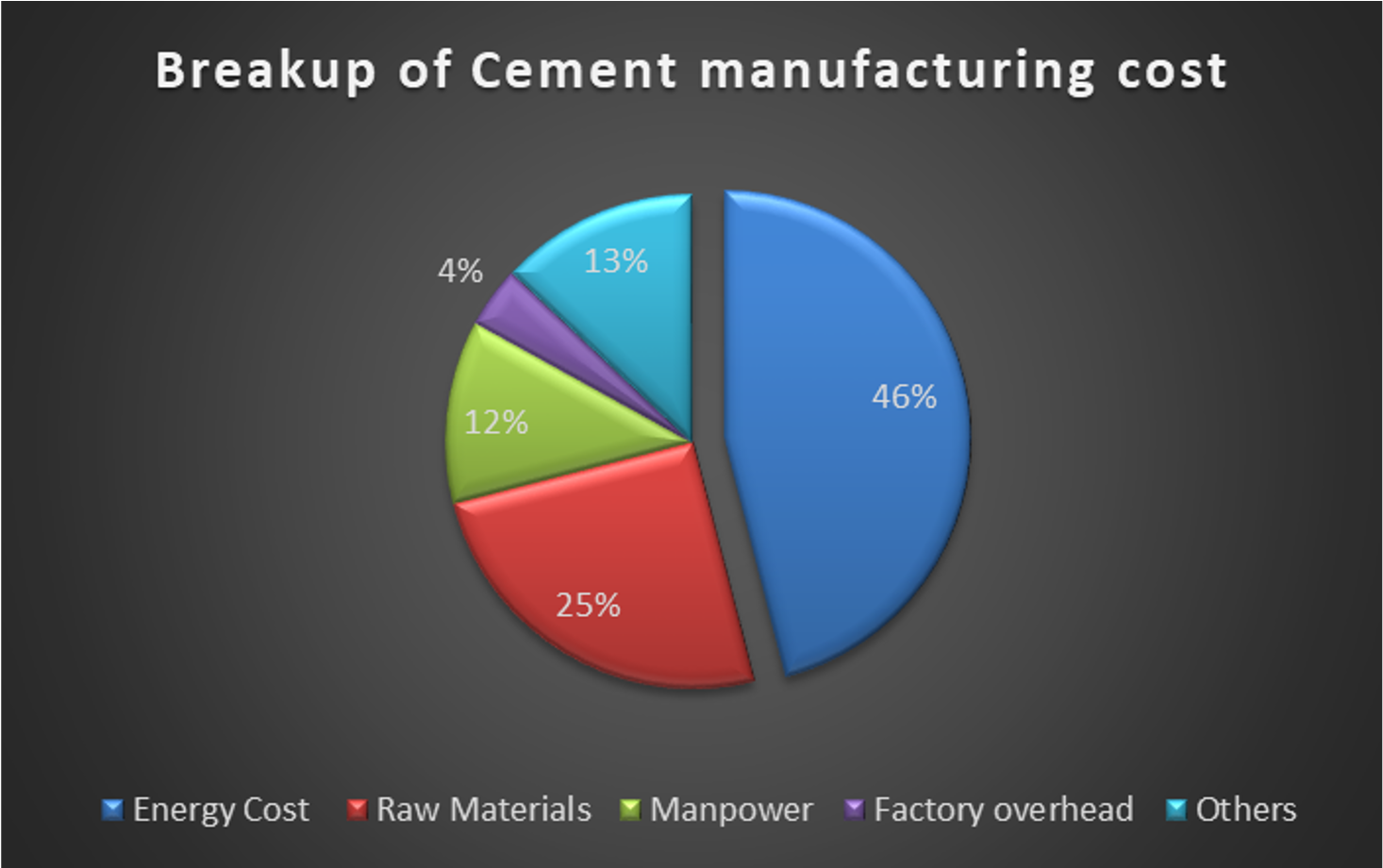

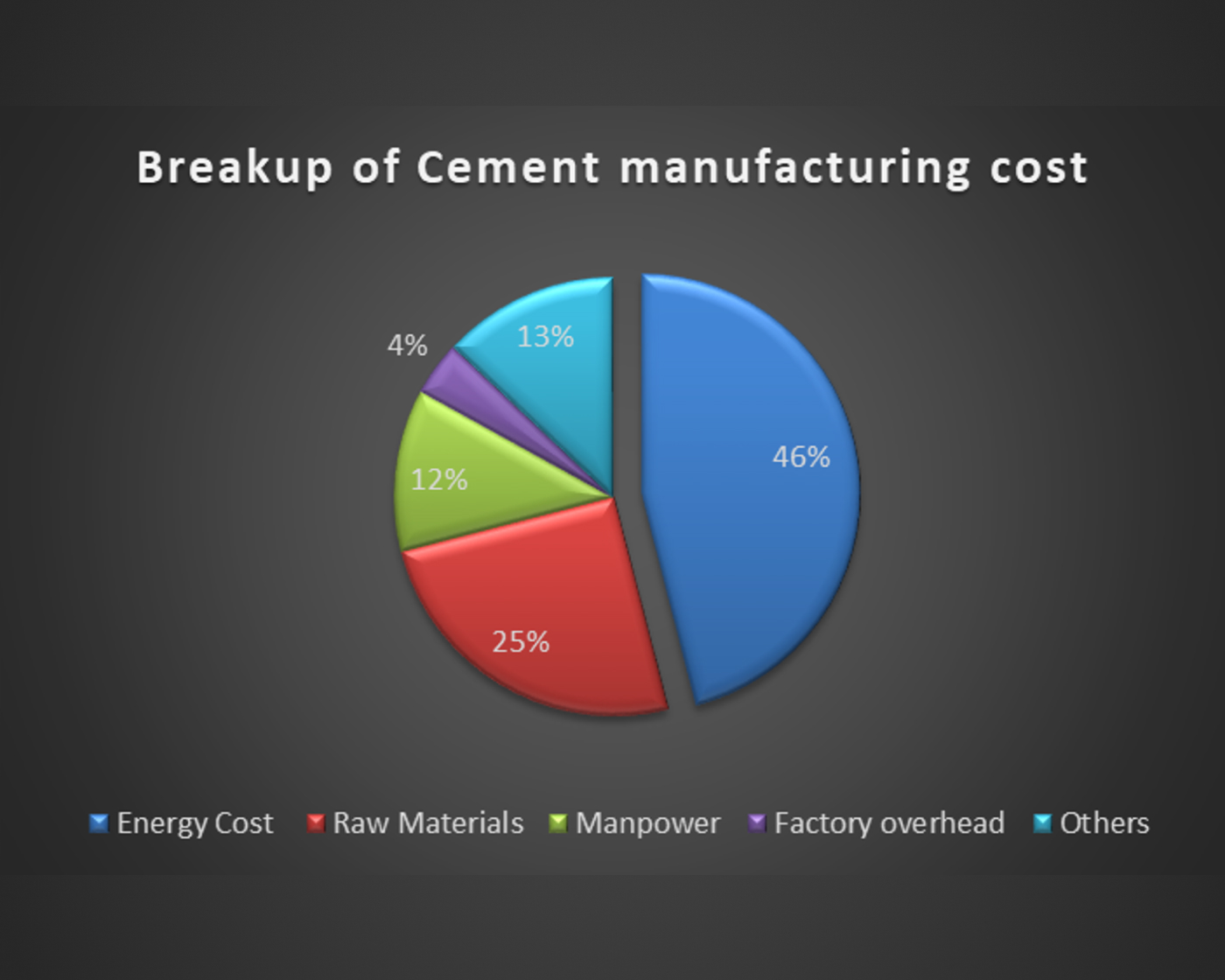

Cement industry is an energy intensive industry and 3rd largest coal consumer in the country after power and steel industry requiring both electrical and thermal energy for its operations. These energy sources not only contribute to significant CO2 emissions but also incur substantial operational costs. Though India has reduced the Specific Energy Consumption (SEC) to ~75 kWh per ton of cement over time (SEC of older plants are still in the range of 80-100 kWh per ton of cement), the Input energy represents almost ~45% of the overall manufacturing expenses thereby making it critical for this industry to explore both cost and environmental conscious alternatives.

The transition to solar energy in the cement industry offers multifaceted benefits.

* Includes fixed charges, variable charges and Electricity duty

Sunsure Energy, a leader in renewable energy solutions, is instrumental in aiding cement companies in India to achieve their RE100 goals. Utilizing innovative approaches like Round-the-Clock (RTC) Power through Open Access Solar, Green Attributes, and Virtual Power Purchase Agreements (PPAs), Sunsure tailors solutions that are both sustainable and economically viable. Among their notable clients in the cement sector is Dalmia Cement (Bharat) Ltd., a leading name in India’s industrial landscape. Sunsure’s solutions enable companies like Dalmia Cement to integrate renewable energy seamlessly, ensuring consistent energy supply and aiding in their journey towards complete renewable energy reliance.

The integration of solar energy in the cement industry is not just an environmental imperative but also a strategic business decision. With the support of companies like Sunsure Energy, the cement industry is well on its way to achieving a greener and more sustainable future.

Harnessing solar energy involves capturing sunlight and converting it into electricity, offering a renewable and cleaner energy source compared to traditional fossil fuels.

The transition is increasingly cost-effective, with solar power systems offering a viable alternative to conventional energy sources.

The landed open access cost of solar power stands at INR ~4-7 per unit, compared to grid power tariffs for C&I units offered by Discoms which is at INR ~8-10 per unit.

The cement industry is known for its energy-intensive processes and substantial carbon emissions. Integrating solar energy into cement manufacturing operations offers various benefits as below,